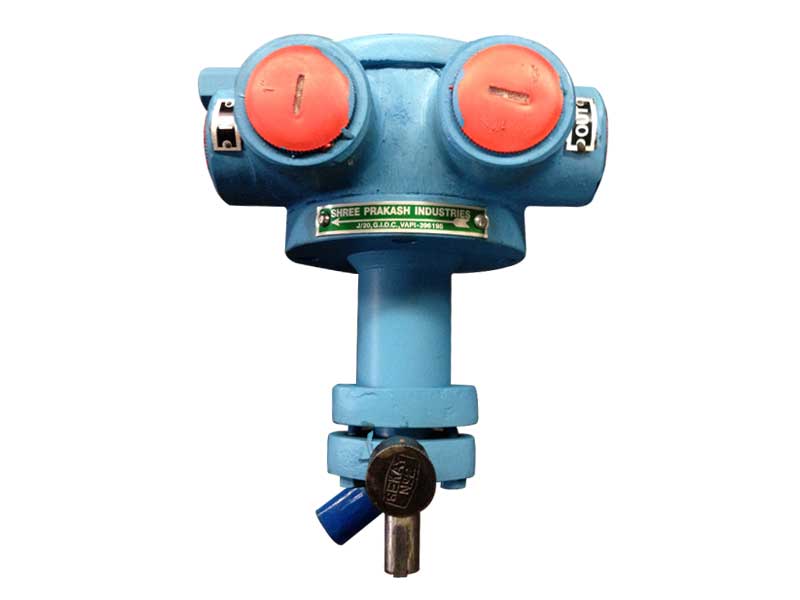

'Swastik' Shuttle Block Pumps

Operating Principle

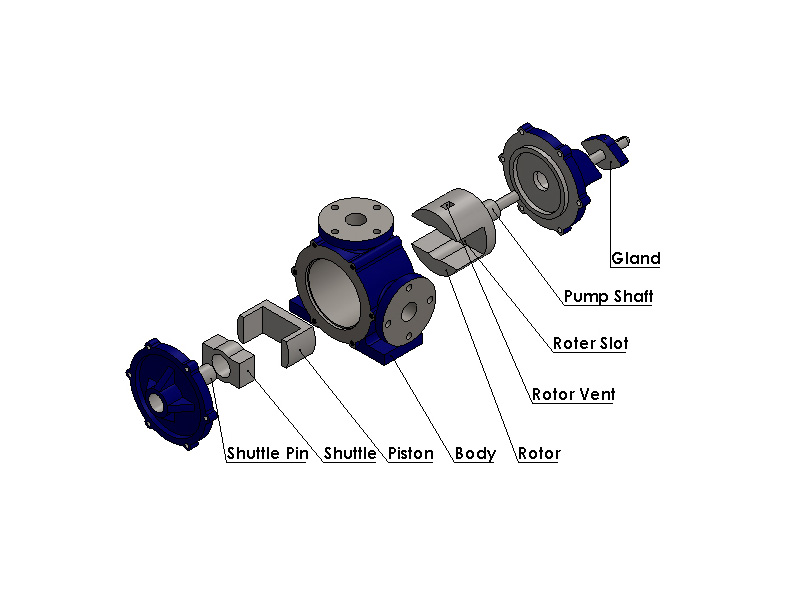

SPI make 'Prakash' Shuttle Block pumps which are Rotary and Piston Combination pumps, have special pumping principle. Two double acting pistons in their cylinders facing each other at right angles complete the action, while the rotor takes turns without any valving. Shuttle Block Pump is a Self-Priming Rotary Pump. Each pump has three main pumping elements-Rotor. Piston and Shuttle. Rotor is attached to a single shaft and runs centrally in pump casing. The face of the Rotor has rectangular slot. The channel-shaped Piston reciprocates within the slot. Shuttle. which is a rectangular block, feeds liquid tight in piston slot and reciprocates. The eccentric Pin, fixed on the pump cover, engages the shuttle bore as the rotor turns in the pump casing and accommodates the reciprocating action of piston in rotor and shuttle in piston. This pump, as an accomplished piston pump, can handle highly viscous liquids or thin volatile material with unique suction characteristics, with smoothness, without any vibration. Shuttle Block Pump handles the product smoothly without causing break-down of the product, emulsion, aeration, chewing, foaming or heating, This unique action of the pump is an advantage, without any extra cost. Shuttle Block Pump is sturdy, easy to maintain and solves difficult pumping problems.

Advantages

- Excellent suction is derived in the pump due to piston type pumping with only four overlapping strokes per revolution. High viscosity liquids including pasty and lumpy substances can be pumped with much ease.

- Provided with single shaft design with one long sleeve-bearing support and external ball bearing, pump is vibration-free. Smooth running and also allows the use of belt/chain drives. Bearing does not get contaminated with pumping fluid.

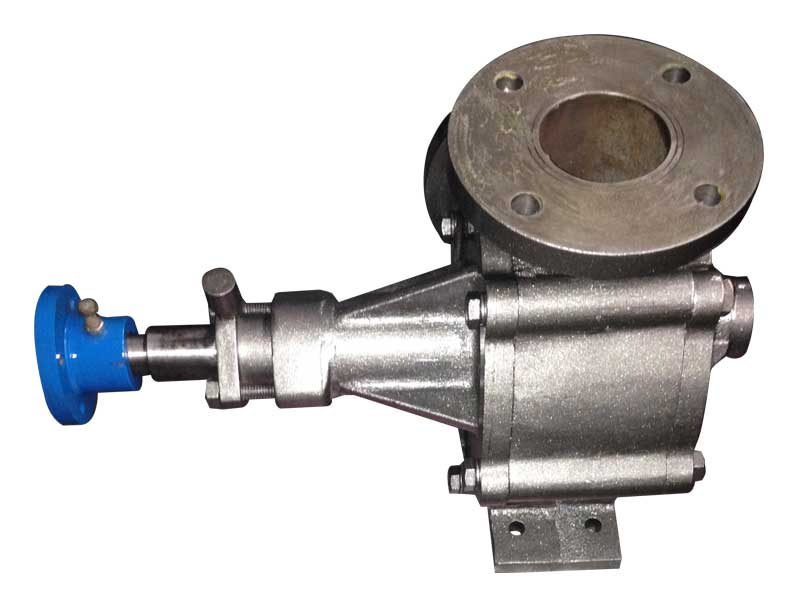

- Inspection and service of pump elements can be done at installation by "FRONT PULL OUT” design without disconnecting pipes, coupling or motor or any other parts by simply unscrewing the cover bolts.

- Contact areas between rotor elements being large, there is low unit pressure and less wear and tear-unlike in gear pumps. Elements are in hydrodynamic balance.

- High reliability and excellent service can be obtained if pump is operating at low speed, thus eliminating extra cost towards maintenance.

- Principle of shuttle block pumping is that the product is moved without share, foaming. agitating, heating emulsifying or chewing -positive advantage over conventional rotary gear pumps.

- Volumetric efficiency is very high, with low power consumption due to correct piston action.

- Single gland construction with external bearings reduces leakages to minimum, unlike four glands required in gear pumps for comparable service.

- Micrometer axial shaft positioning device permits controlled clearance between rotor face and cover and even after long use. wear can be compensated by simple adjustment at site to restore pumping capacity.

Construction

Shuttle block pumps can be supplied in various materials like cast iron, steel, bronze or combination. The pumps can be provided with jacket for heating or cooling and this can be done even on existing installation. Shaft sealing is normally packed gland, but, mechanical seal can also be provided.

Drive

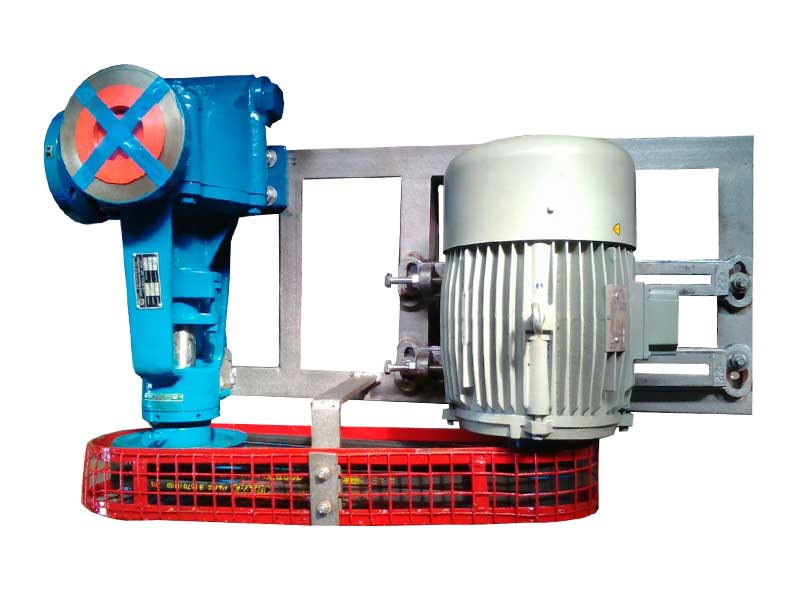

All shuttle block pumps are designed for direct drives or through vee belts, or chain drives without any need for additional bearing supports.

Application

Loading, unloading, transfer, circulations and process pumping of a very wide range of products, from thin oil, like. diesel oil to extremely viscous substance like chocolate. Common applications are unloading of tank lorries and railcars, loading of railcars. tank lorries and barrel filling. For tank to tank transfer and process pumping, the SHUTTLE BLOCK PUMPS are ideal as normal gear pumps or other pumps may fail to perform.

Typical Liquid List

Bitumen, Caustic Soda. Chocolate. Corn Syrup, Coal Tar Pitch, Crude Oil. Enamel, Edible Oils. Fatty Acids, Fuel Oil (LDO, LSHS, HHS. RF, O). Glue-Hot. Grease. Kerosene, Lacquer. Lard-Hot, Linseed Oil. Lubricating Oil. Molasses, Naptha, Palm Oil. Paints. Petroleum. Printing Ink, Resin. Shellac. Soap. Liquor, Sodium Silicate. Starch, Sugar Syrup, Tar. Turpentine. Varnish. Wax. etc.

| Model PI: SB 30 | has four ports. two horizontal and two vertical. |

| Model PI: SB: 100 (Special) | has three ports. two horizontal and one vertical. |

| Model PI: SB: 100-200-450 | have one horizontal and one vertical port. |

| Model PI: SB: 1000 | has only two horizontal ports. |

| Model PI: SB: 100-200-450 (Special) | has only two horizontal ports |

| PORT SIZE | CAPACITY IN LPM AT PRESSURE (PSI) | PRESSURE(PSI) Vs H.P | |||||||||||

| NO | PUMP MODEL | SUCTION | DELIVERY | 0 | 2 | 4 | 6 | 8 | 0 | 2 | 4 | 6 | 8 |

| 1 | PI-SB-30 | 1" | 1" | 46 | 44 | 43.25 | 41.75 | 40.5 | 1 | 1 | 1 | 1 | 1.5 |

| 2 | PI-SB-100 | 1 1/2" | 1 1/2" | 91.5 | 90 | 85 | 82 | 80 | 1 | 1 | 1 | 2 | 2.5 |

| 3 | PI-SB-200 | 2" | 2" | 260 | 257 | 253 | 251 | 244 | 2 | 2.5 | 5 | 5 | 7.5 |

| 4 | PI-SB-450 | 3" | 3" | 452 | 444 | 431 | 415 | 392 | 3 | 3 | 5 | 7.5 | 10 |

| 5 | PI-SB-1000 | 4" | 4" | 970 | 940 | 918 | 851 | ~ | 7.5 | 12 | 20 | ~ | ~ |

All Rights Reserved By Shree Prakash Industries

Designed By Mirackle Solutions