'Max' External Gear Pumps

Applications:

'Prakash' rotary external gear pumps are available for various applications:

Our pumps can be used for various transfer of oils like – light diesel oil, transformer oil, fuel oil, lube oil, castro oil, grease, wax etc..

- With steam jacketed construction for LSHS/Tar pumping.

- In Cast Steel Cast Iron SS-304. SS-316 and Bronze for handling petroleum products, food products & chemicals.

- With hardened and ground gears for handling liquids of low viscosity.

- With profile ground gear for high pressure duties, at low noise levels.

Special Features

| Relief Valve is not required for application Of non-lubricant & corrosive liquids & for pressure higher than 100 K.g./Cm.' and hence not offered. |

| Valve and valve seat of relief valve are hardened and ground for high pressure application from 25 K.g./Cm.' to 100 K.g./Cm.2 |

| Pressure application higher than 8 K.g/Cm.2 are considered high Pressure applications. |

| Profile ground gears are offered for pressure higher than 15 K.g./Cm |

| Direction of rotation can be offered as per requirement |

| Pumps can generally develop negative suction of 4/5 metres and maximum upto 7 metres |

| Pump suction and delivery have BSP connections. Flange connections can be offered on request. |

| Foot or flange mounted pumps can be offered as per requirement. |

| Compact in size, High efficiency, Easy to maintain |

Design & working of 'Prakash' rotary external gear pump

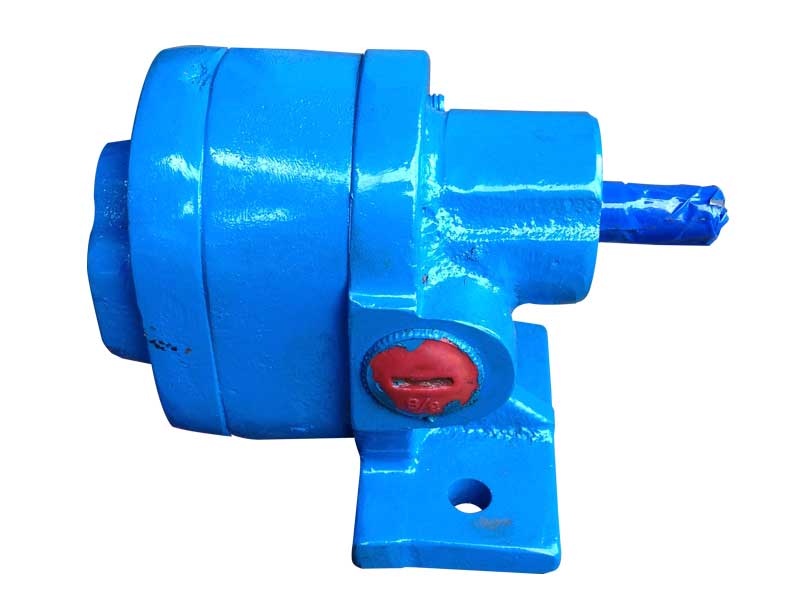

'Prakash' Rotary External Gear Pumps are simple in design and construction. They are built in various sizes and versions to suit every possible industrial application.They are specially designed for handling liquids with very low TO high viscosity, free from abrasive particles and corrosive substances. Pump bodies are designed with due consideration for porting and opening for easy entry for discharge. The gears used are special profile for most efficiency liquid transfer with absolutely noiseless operation.

'Prakash' Rotary External Gear Pumps are essentially constant displacement pumps, pressure range being from 0 K.g./Cm.'upto 20 K.g./Cm.2. These pumps are exclusively used for generating pressure for oil hydraulic devices. Different types of Rotary External Gear Pumps can be offered depending upon required pressure application. THEY are used for application of low to medium high pressure. high pressure in exceptional cases.

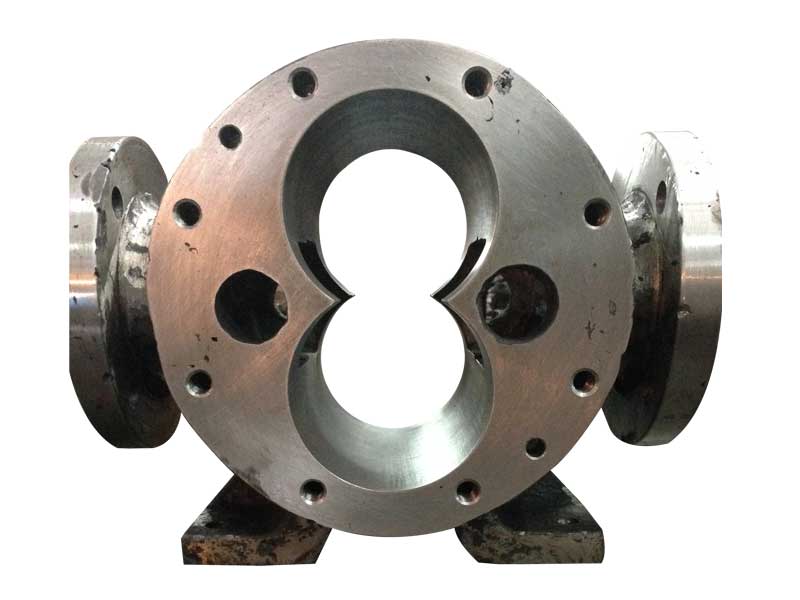

Bearings are located adjacent to the gears and are amply dimensioned for vibration-free running. The bearings are housed in special housing which serve as wear plates and locate the bearing as well as shaft axially as well as at pre-determined center distances. The design permits easy replacement of parts during maintenance. 'Prakash' External Gear Pumps consist of two gears, closely fitted in a housing. Liquid is carried to the periphery of the revolving gears from the suction to the discharge side. The teeth are meshing between the two gears thus preventing return of liquid from suction to discharge side. All components are precision machined and close clearance is maintained between the running parts and the stationary parts to ensure high volumetric efficiency.

Drive

'Prakash' Rotary External Gear Pumps are suitable for either direct Drive through flexible coupling or "V" Belt Drive. or through Gear Box Drive, or through Variable Speed Drives.

Maintenance

Our External Gear Pumps, are robust and sturdy in build, constructed with best of materials to give long working life. Proper maintenance and regular periodical checking will help in giving long and continuous operation life for our pumps.

Note

Pump speeds should be as under depending upon the viscosity of liquids being handled

| Viscosity range of liquid | Pump speed in rpm |

| Upto 1500 | 1500 |

| 1500-5000 | 1000 |

| 5000-15000 | 750 |

| 15000-50000 | 500 |

| Above 50000 | 200-300 |

| Pump capacity is directly proportional to speed. If the liquid being pumped is poor lubricant, pump is operated at lower speeds ranging from 100 to 1000 rmp, depending upon the properties of the liquid. Pumps upto model pi eg:1000 with 250 psi pressure,are offered with hardened and profile ground spur gears in place of single helical/double helical gears, |

|

Applications

| Our Pumps cane be used for transfer of various grades of oils like LIGHT Diesel Oils, Fuel Oils, Transformer Oils Lube Oils, Castor Oil, Grease, Wax Etc. |

| Transfer if chemicals like sodium silicate, caustic soda, resins, Enamels, Adhesives, Fatty Acids Paints, and Varnish, Pulp, Juices, Syrups, Alcohol, Kerosene etc. |

| Atomising of fuel oil at high pressure for burners and boilers |

| Hydraulic systems for presses, power pack units tec. |

| Lubrication of Gear Boxes, cranes, machine tools etc |

| Cooling and filtering in machine tools, Heat transfer liquids for chemicals vessels. |

Special Features

| Relief Valve is not required for application Of non-lubricant & corrosive liquids & for pressure higher than 100 K.g./Cm.' and hence not offered. |

| Valve and valve seat of relief valve are hardened and ground for high pressure application from 25 K.g./Cm.' to 100 K.g./Cm.2 |

| Pressure application higher than 8 K.g/Cm.2 are considered high Pressure applications. Profile ground gears are offered for pressure higher than 15 K.g./Cm |

| Direction of rotation can be offered as per requirement |

| Pumps can generally develop negative suction of 4/5 metres and maximum upto 7 metres |

| Pump suction and delivery have BSP connections. Flange connections can be offered on request. |

| Foot or flange mounted pumps can be offered as per requirement. |

Maintenance

Our pumps are robust and sturdy. Only tested and high quality materials are used for manufacturing our pumps to give durability and long life.

Proper maintenance and regular periodical checking will give continuous operational life.

| NOZEL SIZE | CAPACITY IN LPM AT PRESSURE (PSI) | PRESSURE(PSI) Vs H.P TABLE | RPM | |||||||||

| NO | PUMP MODEL | SUCTION | DELIVERY | 0 | 100 | 250 | 500 | 50 | 100 | 250 | 500 | |

| 1 | PI: EG : 05 | 1/8" | 1/8" | 5 | 3 | 1 | ~ | 0.33 | 0.5 | 0.5 | 0.75 | 1440 |

| 2 | PI: EG : 10 | 3/8" | 3/8" | 12 | 11 | 2 | 7 | 0.33 | 0.75 | 0.75 | 1.5 | 1440 |

| 3 | PI: EG : 15 | 1/2" | 1/2" | 20 | 15 | 10 | 7.5 | 0.5 | 1 | 1.5 | 2 | 1440 |

| 4 | PI: EG : 20 | 3/4" | 3/4" | 25 | 22 | 15 | 15 | 1 | 1.5 | 2 | 3 | 1440 |

| 5 | PI: EG : 30 | 1" | 1" | 35 | 30 | 22 | 25 | 1.5 | 2 | 3 | 5 | 1440 |

| 6 | PI: EG : 40 | 1" | 1" | 45 | 40 | 35 | 30 | 1.5 | 2 | 3 | 5 | 1440 |

| 7 | PI: EG : 50 | 1" | 1" | 60 | 50 | 45 | 40 | 1.5 | 2 | 3 | 5 | 1440 |

| 8 | PI: EG : 100 | 1 1/2" | 1 1/2" | 120 | 110 | 110 | 110 | 2 | 3 | 5 | 10 | 1440 |

| 9 | PI: EG : 200 | 2" | 2" | 235 | 210 | 185 | 185 | 3 | 5 | 12.5 | 25 | 1440 |

| 10 | PI: EG : 350 | 2 1/2" | 2 1/2" | 385 | 320 | 250 | ~ | 5 | 10 | 25 | ~ | 1440 |

| 11 | PI: EG : 500 | 3" | 3" | 550 | 455 | 410 | ~ | 7.5 | 15 | 30 | ~ | 1440 |

| 12 | PI: EG : 700 | 3" | 3" | 750 | 700 | 620 | ~ | 12.5 | 20 | 50 | ~ | 1440 |

| 13 | PI: EG : 1000 | 4" | 4" | 1100 | 1000 | ~ | ~ | 15.5 | 30 | ~ | ~ | 960 |

| 14 | PI: EG : 1500 | 4" | 4" | 1600 | 1500 | ~ | ~ | 25.5 | 60 | ~ | ~ | 960 |

| 15 | PI: EG : 2000 | 6" | 6" | 2100 | 1950 | ~ | ~ | 30.5 | 75 | ~ | ~ | 960 |

| 16 | PI: EG : 3000 | 8" | 8" | 3200 | 3000 | ~ | ~ | 50 | 100 | ~ | ~ | 750 |

All Rights Reserved By Shree Prakash Industries

Designed By Mirackle Solutions